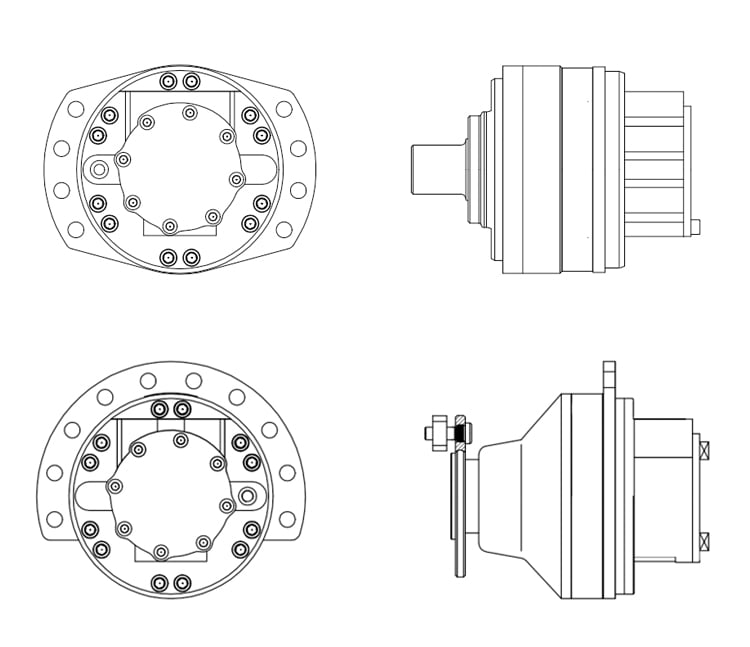

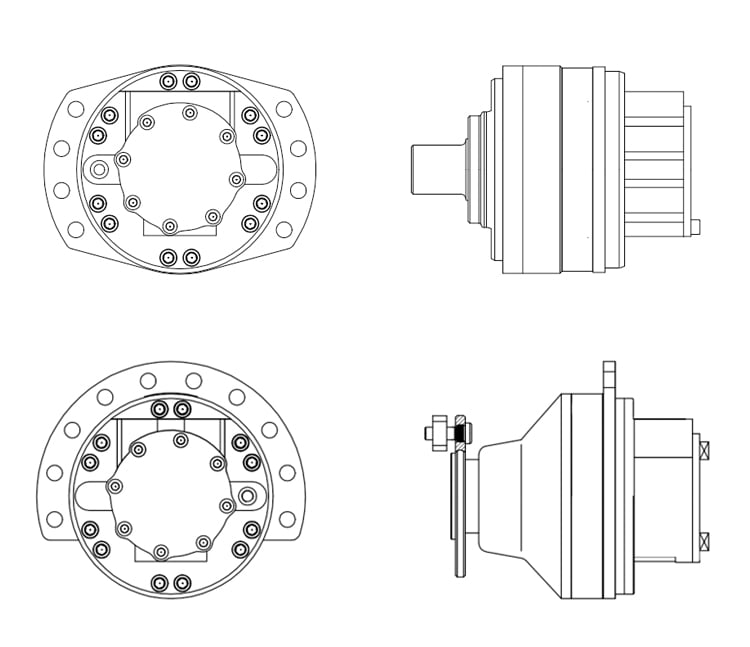

Product Description

Packaging & Delivery

Package Size

24cm * 25cm * 30cm

Package Gross Weight

20kg

| Product name | Rotary Dampers | |

| Shell Material | Cold Steel (Galvanized with Anti-Rust Treatment) | |

| Weight | 50g 52g 54g 56g 58g 60g ,75g,93g,108g | |

| Weight | 70g | |

| Structure | Double Cylinder | |

| Diameter of hinge cup | 35 mm | |

| Connection Hole Size | Hole | |

| Torque | 0.5nm~5.0nm | |

| Life Cycle | 60,000 Times | |

| Package Type | 100 Pieces Per |

Detailed Photos

Q1:What’s the minimum order quantity for the first purchasing?

A1:Normally 1000sets/size is OK.

Q2:How can we get to know the quality before placing an order?

A2:Samples can be provided for quality testing.

Q3:How can we get samples from you?

A3:Free samples can be provided,you just to need take care of the freight by below three ways.

Offering us the courier account

Arranging pick-up service

Paying the freight to us by bank transfer.

Q4:What’s loading capacity for 20ft container?

A4:Max loading capacity is 22tons,exact loading capacity depends on the slide model you choose and the country you come from.For further information,please contact us.

Q5:How long is the delivery time?

A5: 25-35 days after received the deposit.If you have special requirement on delivery time,please let us know.

Q6:What’s the payment terms?

A6:Normally it is ” 30% deposit by T/T, and 70% Balance pay before shipment or against the BL copy”, it depends. Or we can discuss with each other basing on your requirements.

Q7:What should we do if quality defects occurred after received the goods?

A7:Please kindly send us photos with detailed descriptions by email, we will solve it for you immediately,refund or exchange will be arranged once been verified.

Q8:Is it possible to load mix-products in one container?

A8:Yes,it’s available and we can arrange all these for you. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Part: | Dampers |

|---|---|

| Position: | Rear |

| Type: | Hydraulic |

| Samples: |

US$ 3.24/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you explain the role of temperature and pressure in injection molding quality control?

Temperature and pressure are two critical parameters in injection molding that significantly impact the quality control of the process. Let’s explore their roles in more detail:

Temperature:

The temperature in injection molding plays several important roles in ensuring quality control:

1. Material Flow and Fill:

The temperature of the molten plastic material affects its viscosity, or flowability. Higher temperatures reduce the material’s viscosity, allowing it to flow more easily into the mold cavities during the injection phase. Proper temperature control ensures optimal material flow and fill, preventing issues such as short shots, flow marks, or incomplete part filling. Temperature control also helps ensure consistent material properties and dimensional accuracy in the final parts.

2. Melting and Homogenization:

The temperature must be carefully controlled during the melting process to ensure complete melting and homogenization of the plastic material. Insufficient melting can result in unmelted particles or inconsistent material properties, leading to defects in the molded parts. Proper temperature control during the melting phase ensures uniform melting and mixing of additives, enhancing material homogeneity and the overall quality of the molded parts.

3. Cooling and Solidification:

After the molten plastic is injected into the mold, temperature control is crucial during the cooling and solidification phase. Proper cooling rates and uniform cooling help prevent issues such as warping, shrinkage, or part distortion. Controlling the temperature allows for consistent solidification throughout the part, ensuring dimensional stability and minimizing internal stresses. Temperature control also affects the part’s crystallinity and microstructure, which can impact its mechanical properties.

Pressure:

Pressure control is equally important in achieving quality control in injection molding:

1. Material Packing:

During the packing phase of injection molding, pressure is applied to the molten plastic material to compensate for shrinkage as it cools and solidifies. Proper pressure control ensures that the material is adequately packed into the mold cavities, minimizing voids, sinks, or part deformation. Insufficient packing pressure can lead to incomplete filling and poor part quality, while excessive pressure can cause excessive stress, part distortion, or flash.

2. Gate and Flow Control:

The pressure in injection molding influences the flow behavior of the material through the mold. The pressure at the gate, where the molten plastic enters the mold cavity, needs to be carefully controlled. The gate pressure affects the material’s flow rate, filling pattern, and packing efficiency. Optimal gate pressure ensures uniform flow and fill, preventing issues like flow lines, weld lines, or air traps that can compromise part quality.

3. Ejection and Part Release:

Pressure control is essential during the ejection phase to facilitate the easy removal of the molded part from the mold. Adequate ejection pressure helps overcome any adhesion or friction between the part and the mold surfaces, ensuring smooth and damage-free part release. Improper ejection pressure can result in part sticking, part deformation, or mold damage.

4. Process Monitoring and Feedback:

Monitoring and controlling the temperature and pressure parameters in real-time are crucial for quality control. Advanced injection molding machines are equipped with sensors and control systems that continuously monitor temperature and pressure. These systems provide feedback and allow for adjustments during the process to maintain optimum conditions and ensure consistent part quality.

Overall, temperature and pressure control in injection molding are vital for achieving quality control. Proper temperature control ensures optimal material flow, melting, homogenization, cooling, and solidification, while pressure control ensures proper material packing, gate and flow control, ejection, and part release. Monitoring and controlling these parameters throughout the injection molding process contribute to the production of high-quality parts with consistent dimensions, mechanical properties, and surface finish.

Are there specific considerations for choosing injection molded parts in applications with varying environmental conditions or industry standards?

Yes, there are specific considerations to keep in mind when choosing injection molded parts for applications with varying environmental conditions or industry standards. These factors play a crucial role in ensuring that the selected parts can withstand the specific operating conditions and meet the required standards. Here’s a detailed explanation of the considerations for choosing injection molded parts in such applications:

1. Material Selection:

The choice of material for injection molded parts is crucial when considering varying environmental conditions or industry standards. Different materials offer varying levels of resistance to factors such as temperature extremes, UV exposure, chemicals, moisture, or mechanical stress. Understanding the specific environmental conditions and industry requirements is essential in selecting a material that can withstand these conditions while meeting the necessary standards for performance, durability, and safety.

2. Temperature Resistance:

In applications with extreme temperature variations, it is important to choose injection molded parts that can withstand the specific temperature range. Some materials, such as engineering thermoplastics, exhibit excellent high-temperature resistance, while others may be more suitable for low-temperature environments. Consideration should also be given to the potential for thermal expansion or contraction, as it can affect the dimensional stability and overall performance of the parts.

3. Chemical Resistance:

In industries where exposure to chemicals is common, it is critical to select injection molded parts that can resist chemical attack and degradation. Different materials have varying levels of chemical resistance, and it is important to choose a material that is compatible with the specific chemicals present in the application environment. Consideration should also be given to factors such as prolonged exposure, concentration, and frequency of contact with chemicals.

4. UV Stability:

For applications exposed to outdoor environments or intense UV radiation, selecting injection molded parts with UV stability is essential. UV radiation can cause material degradation, discoloration, or loss of mechanical properties over time. Materials with UV stabilizers or additives can provide enhanced resistance to UV radiation, ensuring the longevity and performance of the parts in outdoor or UV-exposed applications.

5. Mechanical Strength and Impact Resistance:

In applications where mechanical stress or impact resistance is critical, choosing injection molded parts with the appropriate mechanical properties is important. Materials with high tensile strength, impact resistance, or toughness can ensure that the parts can withstand the required loads, vibrations, or impacts without failure. Consideration should also be given to factors such as fatigue resistance, abrasion resistance, or flexibility, depending on the specific application requirements.

6. Compliance with Industry Standards:

When selecting injection molded parts for applications governed by industry standards or regulations, it is essential to ensure that the chosen parts comply with the required standards. This includes standards for dimensions, tolerances, safety, flammability, electrical properties, or specific performance criteria. Choosing parts that are certified or tested to meet the relevant industry standards helps ensure compliance and reliability in the intended application.

7. Environmental Considerations:

In today’s environmentally conscious landscape, considering the sustainability and environmental impact of injection molded parts is increasingly important. Choosing materials that are recyclable or biodegradable can align with sustainability goals. Additionally, evaluating factors such as energy consumption during manufacturing, waste reduction, or the use of environmentally friendly manufacturing processes can contribute to environmentally responsible choices.

8. Customization and Design Flexibility:

Lastly, the design flexibility and customization options offered by injection molded parts can be advantageous in meeting specific environmental or industry requirements. Injection molding allows for intricate designs, complex geometries, and the incorporation of features such as gaskets, seals, or mounting points. Customization options for color, texture, or surface finish can also be considered to meet specific branding or aesthetic requirements.

Considering these specific considerations when choosing injection molded parts for applications with varying environmental conditions or industry standards ensures that the selected parts are well-suited for their intended use, providing optimal performance, durability, and compliance with the required standards.

Can you explain the advantages of using injection molding for producing parts?

Injection molding offers several advantages as a manufacturing process for producing parts. It is a widely used technique for creating plastic components with high precision, efficiency, and scalability. Here’s a detailed explanation of the advantages of using injection molding:

1. High Precision and Complexity:

Injection molding allows for the production of parts with high precision and intricate details. The molds used in injection molding are capable of creating complex shapes, fine features, and precise dimensions. This level of precision enables the manufacturing of parts with tight tolerances, ensuring consistent quality and fit.

2. Cost-Effective Mass Production:

Injection molding is a highly efficient process suitable for large-scale production. Once the initial setup, including mold design and fabrication, is completed, the manufacturing process can be automated. Injection molding machines can produce parts rapidly and continuously, resulting in fast and cost-effective production of identical parts. The ability to produce parts in high volumes helps reduce per-unit costs, making injection molding economically advantageous for mass production.

3. Material Versatility:

Injection molding supports a wide range of thermoplastic materials, providing versatility in material selection based on the desired properties of the final part. Various types of plastics can be used in injection molding, including commodity plastics, engineering plastics, and high-performance plastics. Different materials can be chosen to achieve specific characteristics such as strength, flexibility, heat resistance, chemical resistance, or transparency.

4. Strength and Durability:

Injection molded parts can exhibit excellent strength and durability. During the injection molding process, the molten material is uniformly distributed within the mold, resulting in consistent mechanical properties throughout the part. This uniformity enhances the structural integrity of the part, making it suitable for applications that require strength and longevity.

5. Minimal Post-Processing:

Injection molded parts often require minimal post-processing. The high precision and quality achieved during the molding process reduce the need for extensive additional machining or finishing operations. The parts typically come out of the mold with the desired shape, surface finish, and dimensional accuracy, reducing time and costs associated with post-processing activities.

6. Design Flexibility:

Injection molding offers significant design flexibility. The process can accommodate complex geometries, intricate details, undercuts, thin walls, and other design features that may be challenging or costly with other manufacturing methods. Designers have the freedom to create parts with unique shapes and functional requirements. Injection molding also allows for the integration of multiple components or features into a single part, reducing assembly requirements and potential points of failure.

7. Rapid Prototyping:

Injection molding is also used for rapid prototyping. By quickly producing functional prototypes using the same process and materials as the final production parts, designers and engineers can evaluate the part’s form, fit, and function early in the development cycle. Rapid prototyping with injection molding enables faster iterations, reduces development time, and helps identify and address design issues before committing to full-scale production.

8. Environmental Considerations:

Injection molding can have environmental advantages compared to other manufacturing processes. The process generates minimal waste as the excess material can be recycled and reused. Injection molded parts also tend to be lightweight, which can contribute to energy savings during transportation and reduce the overall environmental impact.

In summary, injection molding offers several advantages for producing parts. It provides high precision and complexity, cost-effective mass production, material versatility, strength and durability, minimal post-processing requirements, design flexibility, rapid prototyping capabilities, and environmental considerations. These advantages make injection molding a highly desirable manufacturing process for a wide range of industries, enabling the production of high-quality plastic parts efficiently and economically.

editor by Dream 2024-05-07

China best torque limiter factory manufacturer & supplier Floor Price! 70ton Wide Cab Hydraulic Mobile Truck Crane with top quality & best price

We – EPG Team theTorque values can be modified in the subject, even so the torque limiter should be disassembled and the springs changed to accomplish the new torque value. most significant gearbox & motors , torque limiter couplings and gears manufacturing unit in China with 5 various branches. For more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

70ton broad taxi Hydraulic Moblie Truck Crane (QY70K-I)

Functionality parameters of QY70K-I truck crane

The revolutionary jib system adopts embedded block, plug-in boom head and intercontinental advanced U segment jib, which has superb lifting functionality and protected and reliable lifting work.

•The distinctive stretch and retract method avoids the bend of the main pipe and cylinder and the break of the growth brought on by misoperation, enhancing the basic safety of the operations.

•Eight patent tactics make sure the easy, higher effectiveness and power conservation of the lifting, rotation, and luffing techniques.

•The torque limiter adopts colorful Lcd screen, noticing the intelligence of the failure diagnosis. The precision is forward of the business.

•Adopt the new hydraulic motor with large torque commencing point, ma ept the secondary lifting safer.

•The humanity style makes the cab and management taxi far more roomy, and easy to work.

•Six distinctive producing technologies ensure the high high quality.

•The wor ept situation expands twice. Newly insert 5t counterweight.

| Dimension | Unit | QY70K-I |

| Total duration | mm | 13930 |

| General width | mm | 2800 |

| Total peak | mm | 3575 |

| Excess weight | ||

| Overall weight in vacation | kg | 43000(with out 1t vice counterweight) |

| Front axle load | kg | 17000 |

| Rear axle load | kg | 26000 |

| Electricity | ||

| Motor model | WD615.338(domestic III) | |

| Motor rated electrical power | kW/(r/min) | 276/2200 |

| Engine rated torque | N.m/(r/min) | 1500/1400 |

| Journey | ||

| Max. travel speed | km/h | eighty |

| Min. turning diameter | m | 24 |

| Min. ground clearance | mm | 327 |

| Approach angle | ° | 19 |

| Departure angle | ° | thirteen |

| Max. quality ability | % | forty |

| Gasoline usage for 100km | L | 45 |

| Main efficiency | ||

| Max. rated total lifting capability | t | 70 |

| Min. rated wor ept radius | m | 3000 |

| Turning radius at turntable tail | m | three.55 |

| Max. lifting torque | kN.m | 2303 |

| Base growth | m | eleven.6 |

| Completely prolonged increase | m | forty four.5 |

| Totally prolonged increase+ jib | m | 59.5 |

| Longitudinal outrigger span | m | six.one |

| Lateral outrigger span | m | 7.3 |

| Wor ept velocity | ||

| Boom luffing time | s | sixty |

| Growth complete extension time | s | ≤150 |

| Max. swing speed | r/min | ≥2. |

| Max. velocity of principal winch (solitary rope) (no load) | m/min | ≥130 |

| Max. velocity of aux. winch (single rope) (no load) | m/min | ≥108 |

Truck crane series models:

eight ton truck crane QY8B.five

12 ton truck crane QY12B.5

20 ton truck crane QY20G.five

25 ton truck crane QY25K5-I, QY25K-II

30 ton truck crane QY30K5-I

35 ton truck crane QY35K5

50 ton truck crane QY50K-II

70 ton truck crane QY70K-I

100 ton truck crane QY100K-I

Tough-terrain Crane types:

twenty five ton Tough-terrain Crane RT25(Jib stowed below growth)

twenty five ton Rough-terrain Crane RT25(Facet-positioned Auxiliary Boom)

35 ton Rough-terrain Crane RT35

forty ton Tough-terrain Crane RT40E

50 ton Rough-terrain Crane RT50

60 ton Rough-terrain Crane RT60

70 ton Rough-terrain Crane RT70E

80 ton Tough-terrain Crane RT80

ninety ton Rough-terrain Crane RT90E

100 ton Rough-terrain Crane RT100

The use of first gear manufacturer’s (OEM) part quantities or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating solution use and compatibility. Our firm and the listed substitute areas contained herein are not sponsored, approved, or made by the OEM.

China best torque limiter factory manufacturer & supplier EPT 55ton Hydraulic Truck Crane Qy55V552 Qy55V with Five Section Boom with top quality & best price

We – EPG Team the largest gearbox & motors , torque limiter couplings and gears manufacturing unit in China with 5 different branches. For more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

EPT 55ton hydraulic truck crane QY55V552/QY55V with five area boom

Item Features

ZLJ5425JQZ55V truck crane is a new generation of higher-overall performance merchandise independently designed by our company to fulfill industry need and combine many years of encounter and superior technology. The overall performance parameters of crane lifting top, principal boom length, wor ept speed and lifting potential are currently at the intercontinental foremost amount.

The item is a complete-slewing, telescopic growth-kind, hydraulic proportional-managed truck crane. It adopts the company’s self-created entire-push 4-bridge specific chassis. It has a wide subject of vision, lavish decoration and comfort, 8X4 push, hydraulic electrical power steering, mild and flexible.

The merchandise adopts the latest liquid proportional directional handle valve and quadruple gear pump system, and has basic safety gadgets this sort of as overflow valve, stability valve, hydraulic lock and brake valve to avoid oil passage overload and avoid the trigger of oil pipe rupture. Accidents happen to ensure that the wor ept potential of every employing company is fully utilized, enhancing the dependability and security of the program.

The product is geared up with a assortment of basic safety units this kind of as a torque limiter and a complete lights system to guarantee safe and reputable procedure and effortless evening perform.

The merchandise is novel in condition, with a beautiful body, a stunning line and a lovely shade.

Automotive ept design: ZLJ5425JQZ55V

Engineering ept design: QY55V

Product attribute amount: QY55V552

Optimum rated overall lifting ability kg 55000

Standard arm greatest lifting torque kN.m 2009

Longest primary increase maximum lifting torque kN.m 1050

Basic arm greatest lifting height m twelve.six

Optimum lifting height of major growth m 43.6 Irrespective of growth deformation

Maximum lifting top of the jib m fifty nine.5

Single rope highest pace (principal winch)one hundred Series the Rexnord Autogard one hundred Sequence Torque Limiter is a common function torque overload device that provides lower cost, reliable protection for industrial equiptment. m/min one hundred twenty

One rope greatest speed (sub-winding) m/min a hundred and twenty

Increase boom time s 50

Increase extension time s ninety five

Rotation speed r/min ~2.two

Maximum use altitude m 2000

Highest vacation velocity km/h 76

Maximum grade % 40

Minimum turning diameter m ≤24

Bare minimum ground clearance mm 260

Gas consumption for every 100 km L forty three

Driving self-excess weight (total mass) kg 42000

Car tuning high quality kg 41870

Entrance axle load kg 16000

Rear axle axle load kg 26000

Proportions (duration × width × peak) mm 13700 × 2800 × 3650

Leg longitudinal length m 5.92

The lateral length of the legs is fully extended by 7.ten and half prolonged by 4.80.

Tail radius of gyration mm 3900

Primary arm length m eleven.4~forty three.

Major arm elevation angle ° -2~eighty

Secondary arm length m 9.5, sixteen.

Jib mounting angle ° , thirty

The use of unique products manufacturer’s (OEM) part quantities or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating product use and compatibility. Our firm and the shown substitution parts contained herein are not sponsored, accredited, or produced by the OEM.

China best torque limiter factory manufacturer & supplier Construction Machinery Crane Hydraulic 50 Ton Truck Crane Qy50ka with top quality & best price

We – EPG Group the biggest gearbox & motors , torque limiter couplings and gears manufacturing facility in China with 5 different branches. For a lot more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

Building Machinery Crane Hydraulic fifty ton truck crane QY50KA

Feature:

- Foremost performance: the growth length in full extension is 57.7m, the performance major in 5%. The quality capacity is forty%, which make the device have good street adaptability.

• The distinctive U increase and plug-in boom head make the load-carrying capacity a lot more well balanced, and lift much more smoothly.

• The exclusive extend and retract strategy stops the misoperation the extend and retract of the growth is safer and a lot more reliable.

• The management program is optimized by 8 patents lifting, rotation, and luffing are simple and trustworthy.

• Six distinctive technologies supply the high quality assurance, and make the products keep a higher worth.

• The modern jib technique adopts embedded block, plug-in growth head and octagon jib, which has exceptional lifting performance and safe and reliable lifting function.

• The exclusive extend and retract method avoids the bend of the core pipe and cylinder and the break of the increase triggered by misoperation, enhancing the protection of the operations.

• Eight patent techniques ensure the easy, high performance and power conservation of the lifting, rotation, and luffing programs.

• Adopt the new hydraulic motor with large torque starting up level, ma ept the secondary lifting safer.

• The torque limiter adopts colourful Lcd show, noticing the intelligence of the failure diagnosis. The precision is forward of the industry.

• The humanity style tends to make the taxi and handle taxi much more roomy, and simple to work.

• Six exclusive production systems guarantee the large quality.

Specification:

| Item | Unit | ||

| Dimensions | Overall length | 13770 | mm |

| Overall width | 2800 | mm | |

| All round peak | 3570 | mm | |

| Weight | Dead bodyweight in travel state | 41000 | Kg |

| 1st axle load | 7500 | Kg | |

| 2nd axle load | 7500 | Kg | |

| 3rd axle load | 13000 | Kg | |

| 4th axle load | 13000 | Kg | |

| Power | Engine design | WD615.334 WD615.338 WP10.336 WP10.375 | |

| Engine rated output | 247/2200 276/2200 247/2200 275/2200 | Kw(r/min) | |

| Engine rated torque | 1350(1300~1600) 1500(1300~1600) 1350(1100~1500) 1460(1200~1600) | N.m(r/min) | |

| Travel | Max.vacation velocity | eighty | Km/h |

| Min.turning diameter | 24 | m | |

| Min.floor clearance | 291 | mm | |

| Technique angle | seventeen | . | |

| Departure angle | 11 | . | |

| Max.gradeability | forty | % | |

| Gasoline use of for each 100km | 42 | L | |

| Lifting performance | Max.whole rated lifting load | 50 | t |

| Min. wor ept radius | three | mm | |

| Turning radius at swing table tail | 3482 | m | |

| Foundation increase max.load moment | 1822 | Kn.m | |

| Base boom | eleven.three | m | |

| Full- extended boom | forty two.7 | m | |

| Total-prolonged growth+ jib | 57.seven | m | |

| Outrigger longitudinal distance span | five.ninety one | m | |

| Outrigger lareral length span | six.nine | m | |

| Wor ept speed | Increase elevating time | forty | s |

| Growth telescoping time | 80 | s | |

| Max. slewing speed | 2 | r/min | |

| Primary winch max. pace(no load) | a hundred thirty | m/min | |

| Auxiliary winch max. speed(no load) | 120 | m/min |

Photos:

1.. Which countries do we export to?

Asia: Vietnam, India, Indonesia, Pakistan, Kazakhstan, Uzbekistan, and many others.

Europe: Russia, Belarus, Ukraine, Lithuania, Saudi Arabia, and so forth.

South The united states: Brazil, Chile, Paraguay, Argentina, and many others.

Africa: South Africa, Ethiopia, Libya, Ghana,Algeria,and so forth.

2.What are our positive aspects when compared with other manufacturers/factories?

1)Reputable Top quality: Carefully choose standard makers for supporting spare parts,like engines,bridge,transmissions,and several parts made and developed by ourselves,

usually adapting the ideal components.

2)Aggressive Price: Concentration of mechanized generation in huge quantities minimize

manufacturing price to make certain that our price is aggressive.

3)Services Staff: 1st, our revenue administrators are online 24 hours,completely ready to response your

inquiries at any time. Second, professional maintenance crew with senior technicians,

ready to give support sThe FRICTION DISCS and Travel DISCS continue being in get in touch with retaining the input and output customers rotating as one till a torque overload is skilled.ervices to end users and dealers. Most issues can be solved

within 24 hrs.

4)Fast Shipping and delivery:Underneath normal situation,we can delivery with 10 wor ept days in

manufacturing unit after obtaining pre-payment.

three.Which payment conditions can we take?

Generally we can function on T/T or L/C.

one)On T/T term, 30% payment is essential in ept for generation, 70% equilibrium shall

be compensated ahead of delivery or against the duplicate of authentic B/L for old long cooperation clientele.

2)On L/C expression, a hundred% irrevocable L/C at sight without “delicate clauses” can be acknowledged.

four. How prolonged is the validity of our quotation?

As a reputable provider, basically our price remains stable via a single calendar year, we only adjust

our price tag based on two situations:

1)The charge of USD

2)TheThe value of material

Other inquiries, you should make contact with me straight!!

Peter 0086~13083988828 13858117778921244786

The use of first gear manufacturer’s (OEM) portion quantities or logos , e.g. CASE® and John Deere® are for reference reasons only and for indicating merchandise use and compatibility. Our firm and the shown substitution elements contained herein are not sponsored, authorized, or made by the OEM.

China best torque limiter factory manufacturer & supplier Hot Sale Single Acting High Tonnage Self Lock Hydraulic Jacks for Heavy Lifting with Competitive Price with top quality & best price

We – EPG Group the biggest gearbox & motors , torque limiter couplings and gears factory in China with 5 diverse branches. For far more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

Very hot Sale One Acting Substantial Tonnage Self Lock Hydraulic Jacks EPT CLL 10012 for Heavy Lifting with Competitive Price

Merchandise Attributes:

- EPT safety lock nut cylinders for mechanical load holding for up to 1,000 tons

- Baked enamel outdoors end and plated pistons give superior corrosion resistance

- Overflow port functions as a stroke limiter

- Interchangeable, hardened grooved saddles are standard

- CR-four hundred coupler and dust cap integrated on all cylinder versions

- One-performing load return

Products Complex Diameters:

| Design Variety | Cylinder Capability |

Stroke | Cylinder Successful Location |

Oil Capability |

Collapsed Peak |

Extended Peak |

Exterior Diameter |

Weight |

| ton (kN) | mm | cmtwo | cmthree | mm | mm | mm | kg | |

| SOV-CLL-502 | 50 (496) |

50 | 70,9 | 355 | 164 | 214 | 125 | 15 |

| SOV-CLL-504 | a hundred | 70,9 | 709 | 214 | 314 | one hundred twenty five | twenty | |

| SOV-CLL-506 | 150 | 70,9 | 1064 | 264 | 414 | 125 | 25 | |

| SOV-CLL-508 | two hundred | 70,nine | 1418 | 314 | 514 | one hundred twenty five | 30 | |

| SOV-CLL-5571 | 250 | 70,nine | 1773 | 364 | 614 | a hundred twenty five | 35 | |

| SOV-CLL-5012 | 300 | 70,nine | 2127 | 414 | 714 | 125 | forty | |

| SOV-CLL-1002 | 100 (929) |

fifty | 132,7 | 664 | 187 | 237 | 165 | 30 |

| SOV-CLL-1004 | one hundred | 132,7 | 1327 | 237 | 337 | a hundred sixty five | 39 | |

| SOV-CLL-1006 | one hundred fifty | 132,7 | 1991 | 287 | 437 | 165 | 48 | |

| SOV-CLL-1008 | 200 | 132,seven | 2654 | 337 | 537 | a hundred sixty five | fifty six | |

| SOV-CLL-1571 | 250 | 132,7 | 3318 | 387 | 637 | 165 | 64 | |

| SOV-CLL-10012 | three hundred | 132,7 | 3981 | 437 | 737 | a hundred sixty five | seventy three | |

| SOV-CLL-1502 | 150 (1390) |

50 | 198.6 | 993 | 209 | 259 | 205 | fifty three |

| SOV-CLL-1504 | one hundred | 198,6 | 1986 | 259 | 359 | 205 | 66 | |

| SOV-CLL-1506 | a hundred and fifty | 198,6 | 2979 | 309 | 459 | 205 | seventy eight | |

| SOV-CLL-1508 | 200 | 198,6 | 3972 | 359 | 559 | 205 | 92 | |

| SOV-CLL-15571 | 250 | 198,6 | 4965 | 409 | 659 | 205 | 104 | |

| SOV-CLL-15012 | three hundred | 198,6 | 5958 | 459 | 759 | 205 | 117 | |

| SOV-CLL-2002 | two hundred (1859) |

50 | 265,6 | 1330 | 243 | 293 | 235 | 83 |

| SOV-CLL-2006 | 150 | 265,6 | 3989 | 343 | 493 | 235 | 117 | |

| SOV-CLL-20012 | three hundred | 265,6 | 7995 | 493 | 793 | 235 | one hundred seventy | |

| SOV-CLL-2502 | 250 (2562) |

fifty | 366,1 | 1832 | 249 | 299 | 275 | 116 |

| SOV-CLL-2506 | a hundred and fifty | 366,one | 5496 | 349 | 499 | 275 | 162 | |

| SOV-CLL-25012 | 250 | 366,1 | 1571 | 449 | 799 | 275 | 234 | |

| SOV-CLL-3002 | 300 (3193) |

fifty | 456,two | 2281 | 295 | 345 | 310 | 173 |

| SOV-CLL-3006 | a hundred and fifty | 456,two | 6843 | 395 | 545 | 310 | 233 | |

| SOV-CLL-30012 | three hundred | 456,two | 13740 | 545 | 845 | 310 | 323 | |

| SOV-CLL-4002 | 400 (3919) |

50 | 559,nine | 2800 | 335 | 385 | 350 | 250 |

| SOV-CLL-4006 | 150 | 559,9 | 8399 | 435 | 585 | 350 | 327 | |

| SOV-CLL-40012 | 300 | 559,nine | 16800 | 585 | 885 | 350 | 441 | |

| SOV-CLL-5002 | 500 (5118) |

fifty | 731,1 | 3656 | 375 | 425 | 400 | 367 |

| SOV-CLL-5006 | a hundred and fifty | 731,one | 10959 | 475 | 625 | 400 | 466 | |

| SOV-CLL-50012 | 300 | 731,one | 21930 | 625 | 925 | four hundred | 617 | |

| SOV-CLL-6002 | 600 (5983) |

fifty | 854,eight | 4277 | 395 | 445 | 430 | 446 |

| SOV-CLL-6006 | one hundred fifty | 854,eight | 12830 | 495 | 645 | 430 | 562 | |

| SOV-CLL-60012 | 300 | 854,8 | 25650 | 645 | 945 | 430 | 737 | |

| SOV-CLL-8002 | 800 (8238) |

50 | 1176,nine | 5882 | 455 | 505 | 505 | 709 |

| SOV-CLL-8006 | a hundred and fifty | 1176,nine | 17645 | 555 | 705 | 505 | 870 | |

| SOV-CLL-80012 | three hundred | 1176,nine | 35370 | 705 | 1005 | 505 | 1110 | |

| SOV-CLL-10002 | 1000 (10260) |

fifty | 1466,4 | 7329 | 495 | 545 | 560 | 949 |

| SOV-CLL-10006 | a hundred and fifty | 1466,four | 21986 | 595 | 745 | 560 | 1141 | |

| SOV-CLL-100012 | three hundred | 1466,4 | 43980 | 745 | 1045 | 560 | 1430 |

Versions above 150 ton are also offered with common stroke lengths of a hundred, two hundred and 250 mm.

For light-weight aluminium lock nut cylinders see RACL-series cylinders.

Merchandise Photos:

Application Pictures:

Certifications:

Packaging & Shipping:

Wooden situation & Shipping is specified by customer

Our Services:

A single Yr Warranty,restore and service for the total lifestyle,question report reaction in 24 hrs,and reply in 48 hours.

About our factory:

1. EPT Hydraulic Technologies (ZheJiang )Co., Ltd is a manufacturer engaged in design and manufacturing hydraulic cylinders (potential addresses from 10- 1000 tons), synchronous PLC hydraulic program, hydraulic bumps, hydraulic torque wrenches, and electric torque wrenches, and hydraulic components.

2. Given that the institution in 1995, we effectively reworked from EPT manufacturer for Enerpac, Titan, to produce our personal brand name SOV, and our manufacturing unit has been accredited by CE, ISO9001:2008 consecutively.

three. Our clients includes numerous large Chinese industrial companies, such as China Petroleum, Baosteel, Sinopec, China Point out Grid, Xihu (West Lake) Dis. Shipyards, Electric torque limiters offer you a lot of rewards. Their compact development and the use of substantial quality resources will support you to guarantee productive safety of your device in opposition to momentary overload circumstances. Why a Torque Limiter? The objective is to assure productive security of guy and machine from momentary overload problems. A Torque limiter is a mechanical defense gadget which, when an overload takes place, the load separates from the generate. The limiters with rotating factors (balls or rollers) can be presented with a restrict switch. This permits management of the motor push system and to cease the equipment e.g. Emergency Quit. EPT Group, China Railway Construction Corporation. Our synchronous PLC hydraulic program experienced performed a great function in the China large-speed railway constructions. In 2011, our revenue income attained thirty million USD, ma ept us one of the leaders in the Chinese hydraulic cylinders market place specially in the extra-substantial hydraulic cylinders for industrial area and building field.

We are a manufacturer in Hydraulic tools, such as:

Hydraulic cylinders, jacks (5-1000ton), one performing and double acting, hollow plunger

Hydraulic/ electric powered /pneumatic torque wrench (100-72000Nm)

Hydraulic bolt tensioner (a hundred-11486NM)

Hydraulic pumps, guide and electric kind (max up to 3000bar)

Integrated hydraulic lifting system solutions ( 4-72 details lifting method for house translation or leveling, bridge supporting and tank welding supporting)

Hydraulic nut and couplings. (M50-Tr1000)

FAQ:

Q1: How can make contact with product sales?

A1: Remember to phone: 0086~571-8822571/88220973 685 61366 for pre-revenue or click the get in touch with locate our web site and e mail address.

Q2: How can I buy EPT items in my nation?

A2: You should send us an inquiry or e mail, we will reply to you if there is distributor in your nation.

Q3: Can I have EPT items catalog and value record?

A3: Please pay a visit to our English website: to down load our E-catalog, and send us an e mail for value record.

This fall: How lengthy does it get to get the merchandise if I place an buy?

A4: If items inventory available, right after confirmation of your payment or ept payment, we will pack and deliver in 3-7 days. If you decide on intercontinental parcel service, it can be arrived in 3-7days. If it is by sea shipment, it will just take 15-45days relying on different locations.

Q5: How to make payment?

A5: Very first ship us an inquiry, and we will reply you quotation, if our cost satisfies you, we will put together proforma bill with our ban ept particulars.

Q6: Producing time?

Q6: Make sure you send out us an inquiry for stock situation, if we will not have stock, and it is our regular merchandise (refer to our product), it can be created in 10-20 times. If it is customized, not our normal goods, it will get twenty-forty five days to create.

Our other scorching sale items

Get in touch with:Laura Qian

Mob:+0086~13083988828 13858117778016325719

Tel: +86~13083988828:+86-571-68561366

Fax: 0086-571-88220971:+86-571-68561399

The use of original tools manufacturer’s (OEM) element quantities or logos , e.g. CASE® and John Deere® are for reference functions only and for indicating merchandise use and compatibility. Our firm and the outlined replacement components contained herein are not sponsored, accredited, or made by the OEM.

China best torque limiter factory manufacturer & supplier Competitive Price Single Acting High Tonnage Lock Nut Hydraulic Jack with ISO9001 with top quality & best price

We – EPG Team the largest gearbox & motors , torque limiter couplings and gears manufacturing facility in China with 5 diverse branches. For much more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

Competitive Value Single Performing Large Tonnage Lock Nut Hydraulic Jack With ISO9001

Products Description

Introduction

Piston of solitary performing high tonnage lock nut hydraulic cylinder with mechanical loc ept perform and risk-free mechanical load holding over a prolonged interval of time.

Characteristics

Solitary performing ,load return.

Safety lock nut for mechanical load keeping, can be locked at any situation by mechanical nut inside of the stroke, ensure risk-free operation.

Optional special artificial coating for enhanced corrosion resistance and reduce friction for smoother operation to velocity up the return speed.

Special bearing design withstands side-load up to 5% .

Overflow port functions as a stroke limiter.

Interchangeable, hardened grooved saddles are normal, can be configured 5°ball kind saddle to adapt to imbalance load problems.

Dust ring reduces contamination, extending cylinder lifestyle.

Optional handbook valve to make certain the basic safety of the process of lifting and slipping.

three/8 “- 18NPT coupler and dust cap integrated on all designs.

Apps

Synchronous lifting and alternative of rubber bearing in bridge servicing.

Lifting and routine maintenance in energy producing products in energy plant.

Major engine assembly and fantastic tuning in shipyard.

Diesel motor assembly and good tuning in shipyard.

Prolonged-time assist in push machine routine maintenance.

Parameter

| Model | Capacity | Wor ept Pressure | Coll. Height A |

Stroke | Effective Location | Oil Capacity | Outside Dia. D |

Bore Dia.

E |

Saddle Dia. J |

Excess weight | |||||||||||

| (T) | (MPa) | (mm) | (mm) | (cm2) | (cm3) | (mm) | (mm) | (mm) | (kg) | ||||||||||||

| SOV-CLL-502 | 50 | 70 | 164 | 50 | 71.2 | 356 | 130 | 95 | 71 | 15 | |||||||||||

| SOV-CLL-504 | 214 | 100 | 71.2 | 712 | 130 | 95 | 71 | 20 | |||||||||||||

| SOV-CLL-506 | 264 | 150 | 71.two | 1068 | 130 | 95 | 71 | 25 | |||||||||||||

| SOV-CLL-508 | 314 | 200 | 71.2 | 1424 | 130 | 95 | 71 | 30 | |||||||||||||

| SOV-CLL-5571 | 364 | 250 | 71.two | 1780 | 130 | 95 | 71 | 35 | |||||||||||||

| SOV-CLL-5012 | 414 | 300 | 71.2 | 2136 | 130 | 95 | 71 | 40 | |||||||||||||

| SOV-CLL-1002 | 100 | 70 | 187 | 50 | 133 | 665 | 165 | 130 | 71 | 30 | |||||||||||

| SOV-CLL-1004 | 237 | 100 | 133 | 1330 | 165 | 130 | 71 | 39 | |||||||||||||

| SOV-CLL-1006 | 287 | 150 | 133 | 1995 | 165 | 130 | 71 | 48 | |||||||||||||

| SOV-CLL-1008 | 337 | 200 | 133 | 2660 | 165 | 130 | 71 | 56 | |||||||||||||

| SOV-CLL-1571 | 387 | 250 | 133 | 3325 | 165 | 130 | 71 | 64 | |||||||||||||

| SOV-CLL-10012 | 437 | 300 | 133 | 3990 | 165 | 130 | 71 | 73 | |||||||||||||

| SOV-CLL-1502 | 150 | 70 | 209 | 50 | 197.eight | 989 | 205 | 159 | 130 | 53 | |||||||||||

| SOV-CLL-1504 | 259 | 100 | 197.8 | 1978 | 205 | 159 | 130 | 66 | |||||||||||||

| SOV-CLL-1506 | 309 | 150 | 197.eight | 2967 | 205 | 159 | 130 | 78 | |||||||||||||

| SOV-CLL-1508 | 359 | 200 | 197.eight | 3956 | 205 | 159 | 130 | 92 | |||||||||||||

| SOV-CLL-15571 | 409 | 250 | 197.8 | 4945 | 205 | 159 | 130 | 104 | |||||||||||||

| SOV-CLL-15012 | 459 | 300 | 197.8 | 5934 | 205 | 159 | 130 | 117 | |||||||||||||

| SOV-CLL-2002 | 200 | 70 | 243 | 50 | 266.two | 1331 | 235 | 184 | 130 | 83 | |||||||||||

| SOV-CLL-2006 | 343 | 150 | 266.two | 3993 | 235 | 184 | 130 | 117 | |||||||||||||

| SOV-CLL-20012 | 493 | 300 | 266.two | 7986 | 235 | 184 | 130 | 170 | |||||||||||||

| SOV-CLL-2502 | 250 | 70 | 249 | 50 | 365.nine | 1830 | 275 | 216 | 150 | 116 | |||||||||||

| SOV-CLL-2506 | 349 | 150 | 365.9 | 5489 | 275 | 216 | 150 | 162 | |||||||||||||

| SOV-CLL-25012 | 499 | 300 | 365.nine | 10977 | 275 | 216 | 150 | 234 | |||||||||||||

| SOV-CLL-3002 | 300 | 70 | 295 | 50 | 457.one | 2286 | 310 | 241 | 195 | 173 | |||||||||||

| SOV-CLL-3006 | 395 | 150 | 457.one | 6857 | 310 | 241 | 195 | 233 | |||||||||||||

| SOV-CLL-30012 | 545 | 300 | 457.1 | 13713 | 310 | 241 | 195 | 323 | |||||||||||||

| SOV-CLL-4002 | 400 | 70 | 335 | 50 | 558.4 | 2792 | 350 | 267 | 225 | 250 | |||||||||||

| SOV-CLL-4006 | 435 | 150 | 558.4 | 8376 | 350 | 267 | 225 | 327 | |||||||||||||

| SOV-CLL-40012 | 585 | 300 | 558.four | 16752 | 350 | 267 | 225 | 441 | |||||||||||||

| SOV-CLL-5002 | 500 | 70 | 375 | 50 | 729.3 | 3647 | 400 | 305 | 250 | 367 | |||||||||||

| SOV-CLL-5006 | 475 | 150 | 729.3 | 10940 | 400 | 305 | 250 | 466 | |||||||||||||

| SOV-CLL-50012 | 625 | 300 | 729.three | 21879 | 400 | 305 | 250 | 617 | |||||||||||||

| SOV-CLL-6002 | 600 | 70 | 395 | 50 | 855.nine | 4280 | 430 | 330 | 275 | 446 | |||||||||||

| SOV-CLL-6006 | 495 | 150 | 855.9 | 12839 | 430 | 330 | 275 | 562 | |||||||||||||

| SOV-CLL-60012 | 645 | 300 | 855.9 | 25677 | 430 | 330 | 275 | 737 | |||||||||||||

| SOV-CLL-8002 | 800 | 70 | 455 | 50 | 1177.8 | 5889 | 505 | 387 | 320 | 709 | |||||||||||

| SOV-CLL-8006 | 555 | 150 | 1177.8 | 17667 | 505 | 387 | 320 | 870 | |||||||||||||

| SOV-CLL-80012 | 705 | 300 | 1177.8 | 35334 | 505 | 387 | 320 | 1110 | |||||||||||||

| SOV-CLL-10002 | 1000 | 70 | 495 | 50 | 1463.six | 7318 | 560 | 432 | 360 | 949 | |||||||||||

| SOV-CLL-10006 | 595 | 150 | 1463.6 | 21954 | 560 | 432 | 360 | 1141 | |||||||||||||

| SOV-CLL-100012 | 745 | 300 | 1463.six | 43908 | 560 | 432 | 360 | 1430 | |||||||||||||

Images

Firm Information

EPT is a manufacturer engaged in planning and production hydraulic cylinders (capability addresses from 5- a thousand tons), synchronous PLC hydraulic technique, hydraulic bumps, hydraulic torque wrenches, and electric powered torque wrenches, and hydraulic parts.

Because the establishment in 1995, we effectively transformed from EPT manufacturer for numerous global makes, to generate our possess brand name SOV, and our manufacturing unit has been accredited by CE, ISO9001:2008 consecutively.

Our consumers involves several large Chinese industrial companies, this kind of as China Petroleum, Baosteel, Sinopec, China Point out Grid, Xihu (West Lake) Dis. Shipyards, EPT Group, China Railway Development Corporation. Our synchronous PLC hydraulic method experienced played a wonderful function in the China high-velocity railway constructions. In 2011, our sales profits reached 30 million USD, ma ept us one particular of the leaders in the Chinese hydraulic cylinders industry specifically in the additional-higher hydraulic cylinders for industrial region and design subject.

We are a company in equipment, this sort of as:

- Hydraulic cylinders, jacks (5-1000ton), solitary acting and double performing, hollow plunger

- Hydraulic/ electrical /pneumatic torque wrench (one hundred-72000Nm)

- Hydraulic bolt tensioner (100-11486NM) Hydraulic pullers (5-a hundred ton)

- Hydraulic pumps, guide and electric kind (max up to 3000bar)

- Integrated hydraulic lifting technique answers ( 4-72 details lifting technique for property translation or leveling, bridge supporting and tank welding supporting)

- Hydraulic nut and couplings. (M50-Tr1000)

Certification

Given that the institution in 1995, we successfully reworked from EPT producer for Enerpac, Titan, to produce our personal model SOV, and our manufacturing facility has been accredited by CE, ISO9001:2008 consecutively.

Our Principal Collection Merchandise

1.Hydraulic cylinders, jacks (5-3000ton), solitary performing and double performing, hollow plunger Lower height, extremely stress, lock nut

two.Hydraulic torque wrench, electric powered torque wrench, pneumatic torque wrench (a hundred-160000Nm)

three.Hydraulic bolt tensioner (M24-M600) Hydraulic pullers

4.Hydraulic pumps, guide and electric type (max up to 4000bar)

five.Built-in hydraulic lifting technique solutions ( 4-99 factors lifting system for property translation or leveling, bridge supporting and tank welding supporting)

six.Hydraulic nut and couplings. (M50-Tr1000), hydraulic hose

Our goods have been extensively utilised in industrial discipline such as steel plant, cement sector, chemical and refinery, bridge, railway design and upkeep.

Our Providers

One Calendar year Warranty, repair and services for the total existence, query report reaction in 24 several hours, and reply in 48 several hours.

FAQ

Q1: How can get in touch with income ?

A1: You should call: 0086~571-8822571/88220973-6856 1366 for pre-revenue or click the make contact with discover our internet site and electronic mail tackle.

Q2: How can I buy sov items?

A2: You can send us an e mail or an inquiry , our income offers 24 several hours on-line services.

Q3: How can I get EPT merchandise catalog and price list ?

A3: You can request our product sales guy by an inquiry or check out our site.

This fall: What is the shippment time?

A4:You should ship us an inquiry fist,then if we have stock , the goods will be shipped at ten-15 times right after the payment , if you require custom-produced,it will want 20-thirty days.

Q5:What is the payment time period?

A5: Uaually we sopport 100% T/T , T/T30% in advance, the equilibrium will be paid, L/C at sight, western union.

Speak to informatFor a lot more information on Zero-Max’s mechanical torque limiter overload security gadgets, contact us. Or, click on below to find your nearby sales consultant. Shaft-to-Shaft Mount – Type C By way of Shaft Mount – Kind B Finish of Shaft Mount – Variety J Conclude of Shaft Mount – Sort JF Kind S H-TLC Torque Limitersion

Tel: +86~13083988828: +86-571-6856 1366

Moble: 86~13083988828 13858117778918158366

Internet:

The use of unique products manufacturer’s (OEM) part quantities or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating product use and compatibility. Our company and the outlined substitution elements contained herein are not sponsored, accepted, or made by the OEM.

China best torque limiter factory manufacturer & supplier 100 Ton Single Acting Thin Self Lock Hydraulic Jack with top quality & best price

We – EPG Team the largest gearbox & motors , torque limiter couplings and gears factory in China with 5 distinct branches. For far more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

100 Ton Single Acting Skinny Self Lock Hydraulic Jack EPT CLP 1002

Merchandise Characteristics:

- EPT pancake lock nut cylinders have a flat layout for use in confined locations

- Security lock nut for mechanical load keeping

- Solitary-performing load return

- Particular bearing layout resists sideload forces

- Overflow port features as a stroke limiter

- CR-400 coupler and dust cap included on all versions

Specialized Parameters:

| Product Number |

Cylinder Potential |

Stroke | Cylinder Powerful Area |

Oil Potential |

Collapsed Top(A) |

Extended Peak(B) |

Exterior Diameter(D) |

Excess weight |

| ton (kN) | mm | cmtwo | cm3 | mm | mm | mm | kg | |

| SOV-CLP-602 | 60 | fifty | 86,six | 432 | one hundred twenty five | 175 | 140 | fifteen |

| SOV-CLP-1002 | 100 | fifty | 146,eight | 734 | 137 | 187 | one hundred seventy five | 26 |

| SOV-CLP-1602 | 160 | forty five | 231,3 | 1040 | 148 | 193 | 220 | 44 |

| SOV-CLP-2002 | 200 | 45 | 285,six | 1285 | a hundred and fifty five | 200 | 245 | 57 |

| SOV-CLP-2502 | 260 | 45 | 366,eight | 1650 | 159 | 204 | 275 | 74 |

| SOV-CLP-4002 | 400 | 45 | 559,five | 2517 | 178 | 223 | 350 | 134 |

| SOV-CLP-5002 | 520 | forty five | 730,six | 3287 | 192 | 237 | four hundred | 189 |

Items Photographs:

Application Pictures:

Packaging & Shipping

Wood scenario & Shipping is designated by consumer

Certifications

Our Solutions

A single Yr Guarantee,fix and services for the complete daily life,query report response in 24 hours,and reply in 48 hours.

About our factory:

1. EPT Hydraulic Technology (ZheJiang )Co., Ltd is a manufacturer engaged in style and manufacturing hydraulic cylinders (potential handles from ten- a thousand tons), synchronous PLC hydraulic program, hydraulic bumps, hydraulic torque wrenches, and electric torque wrenches, and hydraulic components.

two. Because the institution in 1995, we efficiently transformed from EPT maker for Enerpac, Titan, to produce our very own manufacturer SOV, and our manufacturing facility has been accepted by CE, ISO9001:2008 consecutively.

3. Our buyers contains many massive Chinese industrial businesses, these kinds of as China Petroleum, Baosteel, Sinopec, China Point out Grid, Xihu (West Lake) Dis. Shipyards, EPT Group, China Railway Development Company. Our synchronous PLC hydraulic method experienced played a great position in the China substantial-speed railway constructions. In 2011, our product sales earnings attained thirty million USD, ma ept us one particular of the leaders in the Chinese hydraulic cylinders market place specially in the added-substantial hydraulic cylinders for industrial location and construction subject.

We are a manufacturer in Hydraulic equipment, these kinds of as:

Hydraulic cylinders, jacks (5-1000ton), solitary acting and double acting, hollow plunger

Hydraulic/ electric powered /pneumatic torque wrench (100-72000Nm)

Hydraulic bolt tensioner (a hundred-11486NM)

Hydraulic pumps, manual and electrical variety (max up to 3000bar)

Integrated hydraulic lifting system remedies ( 4-seventy two points lifting program for home translation or leveling, bridge supporting and tank welding supporting)

Hydraulic nut and couplings. (M50-Tr1000)

Our team

FAQ:

Q1: How can speak to product sales?

A1: Make sure you contact: 0086~571-8822571/88220973 685 61366 for pre-product sales or simply click the make contact with uncover our internet site and email handle.

Q2: How can I buy EPT goods in my c400 Series The four hundred Collection has been developed to meet up with the require for a large-and lower-velocity, cost-free-wheeling torque limiter. It differs from prior ball detent designs by utilizing two sets of balls on concentric pitch circles.ountry?

A2: Make sure you deliver us an inquiry or e-mail, we will reply to you if there is distributor in your nation.

Q3: Can I have EPT items catalog and price tag listing?

A3: Remember to check out our English website: to download our E-catalog, and send us an e-mail for price tag record.

This fall: How long does it just take to get the product if I place an purchase?

A4: If merchandise stock offered, following affirmation of your payment or ept payment, we will pack and supply in 3-7 days. If you pick intercontinental parcel service, it can be arrived in 3-7days. If it is by sea shipment, it will get fifteen-45days relying on different places.

Q5: How to make payment?

A5: First send us an inquiry, and we will reply you quotation, if our price tag fits you, we will prepare proforma invoice with our ban ept specifics.

Q6: Manufacturing time?

Q6: Make sure you deliver us an inquiry for inventory situation, if we will not have inventory, and it is our normal goods (refer to our model), it can be developed in ten-twenty times. If it is custom-made, not our regular merchandise, it will just take twenty-forty five days to produce.

Our other sizzling sale goods

Contact:Laura Qian

Mob:+0086~13083988828 13858117778016325719

Tel: +86~13083988828:+86-571-68561366

Fax: 0086-571-88220971:+86-571-68561399

The use of original equipment manufacturer’s (OEM) portion figures or emblems , e.g. CASE® and John Deere® are for reference functions only and for indicating solution use and compatibility. Our business and the shown alternative components contained herein are not sponsored, accepted, or created by the OEM.

China best torque limiter factory manufacturer & supplier Cll-1008 Single Acting Lock Nut Steel Hydraulic Cylinder with top quality & best price

We – EPG Group the largest gearbox & motors , torque limiter couplings and gears factory in China with 5 various branches. For much more particulars: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

1&period EPT security lock nut cylinders for mechanical load holding for up to 1&comma000 tons

2&time period Baked enamel outside the house complete and plated pistons offer outstanding corrosion resistance

three&period Overflow port capabilities as a stroke limiter

four&period Interchangeable&comma hardened grooved saddles are normal

five&period of time CR-four hundred coupler and dust cap included on all cylinder models

6&interval One-performing load return

Parameter

| Product Quantity | Cylinder Ability |

Stroke | Cylinder Powerful Location |

Oil Potential |

Collapsed Peak&lparA&rpar |

Extended Top&lparB&rpar |

Exterior Diameter&lparD&rpar |

Fat |

| ton &lparkN&rpar | mm | cm2 | cm3 | mm | mm | mm | kg | |

| SOV-CLL-502 | 50 &lpar496&rpar |

50 | 70&comma9 | 355 | 164 | 214 | 125 | 15 |

| SOV-CLL-504 | a hundred | 70&comma9 | 709 | 214 | 314 | a hundred twenty five | twenty | |

| SOV-CLL-506 | a hundred and fifty | 70&comma9 | 1064 | 264 | 414 | 125 | twenty five | |

| SOV-CLL-508 | 200 | 70&comma9 | 1418 | 314 | 514 | a hundred twenty five | 30 | |

| SOV-CLL-5571 | 250 | 70&comma9 | 1773 | 364 | 614 | one hundred twenty five | 35 | |

| SOV-CLL-5012 | 300 | 70&comma9 | 2127 | 414 | 714 | 125 | forty | |

| SOV-CLL-1002 | 100 &lpar929&rpar |

50 | 132&comma7 | 664 | 187 | 237 | one hundred sixty five | 30 |

| SOV-CLL-1004 | 100 | 132&comma7 | 1327 | 237 | 337 | one hundred sixty five | 39 | |

| SOV-CLL-1006 | one hundred fifty | 132&comma&period7 | 1991 | 287 | 437 | a hundred sixty five | forty eight | |

| SOV-CLL-1008 | two hundred | 132&comma7 | 2654 | 337 | 537 | one hundred sixty five | 56 | |

| SOV-CLL-1571 | 250 | 132&comma7 | 3318 | 387 | 637 | a hundred sixty five | sixty four | |

| SOV-CLL-10012 | three hundred | 132&comma7 | 3981 | 437 | 737 | 165 | 73 | |

| SOV-CLL-1502 | 150 &lpar1390&rpar |

fifty | 198&period6 | 993 | 209 | 259 | 205 | fifty three |

| SOV-CLL-1504 | a hundred | 198&comma6 | 1986 | 259 | 359 | 205 | 66 | |

| SOV-CLL-1506 | 150 | 198&comma6 | 2979 | 309 | 459 | 205 | 78 | |

| SOV-CLL-1508 | two hundred | 198&comma6 | 3972 | 359 | 559 | 205 | 92 | |

| SOV-CLL-15571 | 250 | 198&comma6 | 4965 | 409 | 659 | 205 | 104 | |

| SOV-CLL-15012 | 300 | 198&comma6 | 5958 | 459 | 759 | 205 | 117 | |

| SOV-CLL-2002 | 200 &lpar1859&rpar |

fifty | 265&comma6 | 1330 | 243 | 293 | 235 | eighty three |

| SOV-CLL-2006 | one hundred fifty | 265&comma6 | 3989 | 343 | 493 | 235 | 117 | |

| SOV-CLL-20012 | 300 | 265&comma6 | 7995 | 493 | 793 | 235 | 170 | |

| SOV-CLL-2502 | 250 &lpar2562&rpar |

fifty | 366&comma1 | 1832 | 249 | 299 | 275 | 116 |

| SOV-CLL-2506 | 150 | 366&comma1 | 5496 | 349 | 499 | 275 | 162 | |

| SOV-CLL-25012 | 250 | 366&comma1 | 1571 | 449 | 799 | 275 | 234 | |

| SOV-CLL-3002 | 300 &lpar3193&rpar |

fifty | 456&comma2 | 2281 | 295 | 345 | 310 | 173 |

| SOV-CLL-3006 | 150 | 456&comma2 | 6843 | 395 | 545 | 310 | 233 | |

| SOV-CLL-30012 | three hundred | 456&comma2 | 13740 | 545 | 845 | 310 | 323 | |

| SOV-CLL-4002 | 400 &lpar3919&rpar |

fifty | 559&comma9 | 2800 | 335 | 385 | 350 | 250 |

| SOV-CLL-4006 | 150 | 559&comma9 | 8399 | 435 | 585 | 350 | 327 | |

| SOV-CLL-40012 | three hundred | 559&comma9 | 16800 | 585 | 885 | 350 | 441 | |

| SOV-CLL-5002 | 500 &lpar5118&rpar |

50 | 731&comma1 | 3656 | 375 | 425 | 400 | 367 |

| SOV-CLL-5006 | one hundred fifty | 731&comma1 | 10959 | 475 | 625 | 400 | 466 | |

| SOV-CLL-50012 | three hundred | 731&comma1 | 21930 | 625 | 925 | four hundred | 617 | |

| SOV-CLL-6002 | 600 &lpar5983&rpar |

fifty | 854&comma8 | 4277 | 395 | 445 | 430 | 446 |

| SOV-CLL-6006 | 150 | 854&comma8 | 12830 | 495 | 645 | 430 | 562 | |

| SOV-CLL-60012 | 300 | 854&comma8 | 25650 | 645 | 945 | 430 | 737 | |

| SOV-CLL-8002 | 800 &lpar8238&rpar |

fifty | 1176&comma9 | 5882 | 455 | 505 | 505 | 709 |

| SOV-CLL-8006 | one hundred fifty | 1176&comma9 | 17645 | 555 | 705 | 505 | 870 | |

| SOV-CLL-80012 | three hundred | 1176&comma9 | 35370 | 705 | 1005 | 505 | 1110 | |

| SOV-CLL-10002 | 1000 &lpar10260&rpar |

50 | 1466&comma4 | 7329 | 495 | 545 | 560 | 949 |

| SOV-CLL-10006 | a hundred and fifty | 1466&comma4 | 21986 | 595 | 745 | 560 | 1141 | |

| SOV-CLL-100012 | three hundred | 1466&comma4 | 43980 | 745 | 1045 | 560 | 1430 |

Firm data

ZheJiang EPT Hydraulic Technologies Co&period of time&comma Ltd is a maker engaged in style and manufacturing hydraulic cylinders &lparcapacity covers from ten- 1000 tons&rpar&comma synchronous PLC hydraulic method&comma hydraulic bumps&comma hydraulic torque wrenches&comma and electric torque wrenches&comma and hydraulic elements&time period

Certification

Considering that the establishment in 1995&comma we productively remodeled from EPT producer for Enerpac&comma Titan&comma to develop our personal manufacturer SOV&comma and our manufacturing facility has been authorized by CE&comma ISO9001&colon2008 consecutively&period of time

Clients

Our customers contains several massive Chinese industrial firms&comma this kind of as China Petroleum&comma Baosteel&comma Sinopec&comma China Point out Grid&comma Xihu (West Lake) Dis. Shipyards&comma EPT Group&comma China Railway Construction Corporation&period of time Our synchronous PLC hydraulic program experienced played a excellent position in the China large-speed railway constructions&time period In 2011&comma our product sales profits reached 30 million USD&comma ma ept us one particular of the leaders in the Chinese hydraulic cylinders marketplace particularly in the further-large hydraulic cylinders for industrial region and design area&period

Principal Merchandise

We are a maker in tools&comma these kinds of as&colon

&bulletHydraulic cylinders&comma jacks &lpar5-3000ton&rpar&comma single acting and double performing&comma hollow plunger&semi reduced height&comma ultra stress&comma lock nut

&bulletHydraulic torque wrench&comma electrical torque wrench&comma pneumatic torque wrench &lpar100-160000Nm&rpar&semi

&bulletHydraulic bolt tensioner &lparM24-M600&rpar&semi Hydraulic pullers&semi

&bulletHydraulic pumps&comma handbook and electric variety &lparmax up to 4000bar&rpar&semi

&bulletIntegrated hydraulic lifting method solutions &lpar 4-ninety nine factors lifting technique for property translation or leveling&comma bridge supporting and tank welding supporting&rpar

&bulletHydraulic nut and couplings&period &lparM50-Tr1000&rpar&comma hydraulic hose

Our products have been commonly utilised in industrial subject these kinds of as steel plant&comma cement industry&comma chemical and refinery&comma bridge&comma railway construction and routine maintenance&time period

WHY DO YOU Need SOV&quest

Q1&colon What is the model title of your goods&quest

A&colon Possess manufacturer “SOV”&comma WE ARE GERMANY OWNED Manufacturing facility&period EPT is also available as required&period

Q2&colon Hydraulic cylinder inside leakage&quest

A&colon There are 3 major motives triggering inner leakage&colon Overload&comma sharpening is not well managed&comma poor seal kits&period of time As is acknowledged to all&comma autos in China are often overload&comma our items all created to bear the overload electricity&interval We have numerical control machine to assure the polish processing &periodAnd we use the imported seals to meet customers’ needs&period

Q3&colon Does your piston rod get ruptured very easily&quest

A&colon Challenging chrome plating quenched and tempered forty five&num steel for piston rod to assure ample hardness and toughness&time period

Q4&colon Is your design realistic&quest What about your product safe coefficient&quest

A&colon We have R&D crew with plentiful layout expertise&period of time We also established production&comma schooling&comma and investigation cooperation with universities&period of time Rest certain&period

Q5&colon How about the supply time&quest

A&colon Above a thousand sets sophisticated equipments to meet customer’s large desire in shortEvery Zero-Max torque limiter is manufactured from resilient warmth dealt with steel for a lengthy operational daily life. shipping time&interval Usually&comma it is 7-twenty days&period of time

Q6&colon What is the right after-support&quest

A&colon If the quality cannot fulfill your necessity&comma we will pay all your misplaced and provide technical support to fix your difficulty&period

The use of unique gear manufacturer’s (OEM) element numbers or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating product use and compatibility. Our business and the outlined replacement components contained herein are not sponsored, accepted, or produced by the OEM.

China manufacturer & factory supplier for china in Faisalabad Pakistan supplier factory exporter hydraulic motor with brake With high quality best price & service

factory of roller chains. Conveyor chains, engineered chains, silent chains, and tabletop chains are also available. Other energy transmission products consist of pillow blocks, conveyor idlers, conveyor pulleys, drive shafts, equipment racks, gear reducers, gears, overrunning clutches, motor bases, pulleys, screw conveyors, shaft couplings, sheaves, speed reducers, sprockets, tapered bushings, tensioners, torque limiters, and universal joints. Services this sort of as bearing reconditioning and repair, ball screw restore, custom contract machining, gearbox mend and overrunning clutch fix services are offered. Roller chains can be employed in conveyor and equipment manufacturing, industrial processing, equipment rebuilding, squander h2o, sand and gravel, instrument and die, metal, metals and scrap processing industrial programs.Innovative thermo remedy equipment, such as network warmth remedy oven, multi-use thermo therapy oven, etc.

Overview

Quick Information

- Following Warranty Support:

-

Video technical help

- Regional Service Location:

-

Egypt

- Showroom Place:

-

Egypt

- Type:

-

areas

- After-income Support Provided:

-

Movie specialized assist

Supply Ability

- Source Ability:

- 3000 Piece/Items for each Thirty day period

Packaging & Supply

- Packaging Details

- packaged in plywood scenario or PALLET

- Port

- NINGBO/SHANGHAI, CHINA

-

Guide Time

: -

Quantity(Bags) 1 – 20 >20 Est. Time(days) 15 To be negotiated

On the web Customization

| TYPE |

Displacement (ml/r) |

Stress (Mpa) |

Torque (N.M) |

Pace range |

Max Cont Power |

|||

|

SinglAdhering to “Survival by Good quality, Advancement by Technology & Credit”, The business will continually improve product efficiency to fulfill the escalating client specifications in the arduous style of perform. e Pace |

Double Speed |

Peak strain |

Cont Pressure |

Rate torque |

Theoric torque |

|||

| TMS08-630 | 627 | 314 | forty | twenty five | 2371 | ninety four | -170 | 36 |

| TMS08-seven hundred | 702 | 351 | 40 | twenty five | 2654 | 106 | -a hundred and seventy | 36 |

| TMS08-780 | Our PTO travel shafts enable the user straightforward upkeep. The greasing nipples on normal crosses are positioned beneath angle to allow the consumer much better accessibility. Easier entry is also attainable simply because of the versatile cone. We listened to the needs of our consumers and positioned the greasing nipple at extensive-angle PTO’s into the cross bearing. The other novelty, we introduced with extensive-angle PTO push shafts is in line greasing. We desired to moreover simplify the routine maintenance and extend the lifespan of joints.780 | 390 | 40 | twenty five | 2949 | 117 | -one hundred seventy | 36 |

| TMS08-860 | 857 | 429 | 40 | twenty five | 3241 | 129 | -a hundred and seventy | 36 |

| TMS08-930 | 934 | 467 | forty | twenty five | 3532 | 141 | -a hundred and seventy | 36 |

| TMS08-1050 | 1043 | 522 | 35 | twenty five | 3944 | 157 | -100 | 36 |

| TMS08-1150 | 1146 | 573 | 35 | 25 | 4333 | 173 | -a hundred | 36 |

| TMS08-1250 | 1248 | 624 | 35 | twenty five | 4719 | 188 | -90 | 36 |

| TYPE |

Displacement (ml/r) |

Force (Mpa) |

Torque (N.M) |

Speed range |

Max Cont Power |

|||

|

Solitary Speed |

Double Pace |

Peak force |

Cont Strain |

Charge torque |

Theoric torque |

|||

| TMS11-840 | 837 | 419 | 40 | twenty five | 3165 | 126 | -a hundred and fifty | forty four |

| TMS11-950 | 943 | 472 | 40 | twenty five | 3566 | 142 | -one hundred fifty | forty four |

| TMS11-1050 | 1048 | 524 | 40 | 25 | 3963 | 158 | -one hundred fifty | forty four |

| TMS11-1260 | 1259 | 630 | forty | 25 | 4761 | one hundred ninety | -a hundred and fifty | forty four |

| TMS11-1270 | 1263 | 632 | 35 | twenty five | 4776 | 191 | -150 | forty four |

| TMS11-1400 | 1404 | 702 | 35 | 25 | 5309 | 212 | -eighty | 44 |

| TMS11-1550 | 1536 | 768 | 35 | twenty five | 5808 | 232 | -80 | 44 |

| TMS11-1700 | 1687 | 844 | 35 | twenty five | 6379 | 255 | -eighty | 44 |

RV025~RV150 Strong Shaft Enter RV025~RV150 Functions: 1. High quality aluminum alloy gear box, mild bodyweight and not rust 2. 2 optional worm wheel resources: Tin (Stannum) bronze or aluminum bronze alloy 3. Normal components and quite versatile for shaft configurations and motor flange interface 4. Many optional mounting alternatives 5. Reduced noise, High effectiveness in heat dissipation

China best torque limiter factory manufacturer & supplier Hydraulic Truck Crane EPT MG Qy100K-I 100 Ton Mobile Crane with top quality & best price

We – EPG Team the most significant gearbox & motors , torque limiter couplings and gears manufacturing unit in China with 5 various branches. For much more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

EPT Truck Crane QY100K-I

one. Engine product: TAD720VE OM457LAIII/nine

two. Max. Lifting load: 100ton

three. Rated electricity: 360kW

The innovative jib program adopts embedded block, plug-in growth head and international superior U area jib, which has outstanding lifting efficiency and safe and reliable lifting operate.

The exclusive extend and retract method avoids the bend of the core pipe and cylinder and the split of the growth caused by misoperation, bettering the protection of the operations.

Eight patent techniqueThe Generate HUB slides over the SHAFT. The generate hub contains a keyway which corresponds to the keyseat in the SHAFT. When a Key is in location, the two customers are linked. The clutch is locked on to the SHAFT with Established SCREWS.s make certain the smooth, high efficiency and vitality conservation of the lifting, rotation, and luffing systems.

The torque limiter adopts colourful Liquid crystal display show, recognizing the intelligence of the failure analysis. The precision is in advance of the sector.

Adopt the new hydraulic motor with big torque beginning point, ma ept the secondary lifting safer.

The humanity design tends to make the taxi and management taxi far more spacious, and easy to run.

Six unique manufacturing technologies make sure the higher quality.

The wor ept issue expands 2 times. Recently incorporate 5t counterweight.

| Dimension | Unit | QY100K-I |

| Overall length, width, peak | mm | 15600×3000×3850 |

| Wheel foundation | mm | 1420+2420+1800+1420+1505 |

| Excess weight | ||

| Whole bodyweight in vacation | kg | 54900 58000 |

| Axle load | ||

| Axle one | kg | 7500 7500 |

| Axle 2 | kg | 7500 7500 |

| Axle 3 | kg | 8300 10000 |

| Axle 4 | kg | 12000 12500 |

| Axle five | kg | 12000 12500 |

| Axle six | kg | 7600 8000 |

| Energy | ||

| Motor rated electrical power | kW/(r/min) | 360/1800 (306/1900) |

| Engine rated torque | N.m/(r/min) | 2200/1300 (2571/1200) |

| Motor rated pace | r/min | 1800 (1900) |

| Min. ground clearance | mm | 310 |

| Travel | ||

| Method angle | ° | twenty |

| Departure angle | ° | 14 |

| Bra ept length (at 30km/h) | m | ≤10 |

| Max. quality potential | % | forty |

| Min. turning diameter | m | 24 |

| Gas consumption for 100km | L | 70 |

| Main overall performance | ||

| Max. rated overall lifting capability | m | 100 |

| Min. rated wor ept radius | three | |

| Turning radius at turntable tail | ||

| Counterweight | mm | 4200 |

| Aux. winch | mm | 4590 |

| Max. lifting torque | 3450 | |

| Base growth | kN.m | 3450(4m×88t) |

| Totally extended boom | kN.m | 1950(24m×7.1t) |

| Entirely extended increase+ jib | kN.m | 1230(19.2m×6t) |

| Outrigger span (entire extension) | ||

| Longitudinal | m | 7.fifty six |

| Lateral | m | seven.six |

| Lifting height | ||

| Foundation increase | m | 13.5 |

| Completely prolonged increase | m | 50.nine |

| Completely extended increase+ jib | m | 70.four |

| Increase size | m | thirteen.5 |

| Entirely prolonged boom | m | fifty one |

| Totally extended boom+ jib | m | 51+18.1+4 |

| Wor ept velocity | ||

| Jib placing angle | ° | ,fifteen,30 |

| Boom luffing time | s | 75 |

| Growth | ||

| Growth telescoping time | ||

| Entire extension | s | a hundred and sixty |

| Max. swing velocity | r/min | 2 |

| Outrigger extension/retraction time | ||

| Outrigger beam in extension/retraction | s | twenty five/15 |

| Outrigger jack in extension/retraction | s | forty five/twenty five |

| Lifting velocity (one rope, layer 4) | ||

| Primary winch | m/min | a hundred and five |

| Aux. winch | m/min | 104 |

The use of original gear manufacturer’s (OEM) component figures or logos , e.g. CASE® and John Deere® are for reference reasons only and for indicating item use and compatibility. Our organization and the shown alternative elements contained herein are not sponsored, approved, or manufactured by the OEM.